GYC's Antistatic Additive Revolutionizes Injection Molding

In the world of making things, keeping them free from static is super important for quality. Flamingo India, a trusted distributor, knows this well. They recently helped a factory with a big problem.

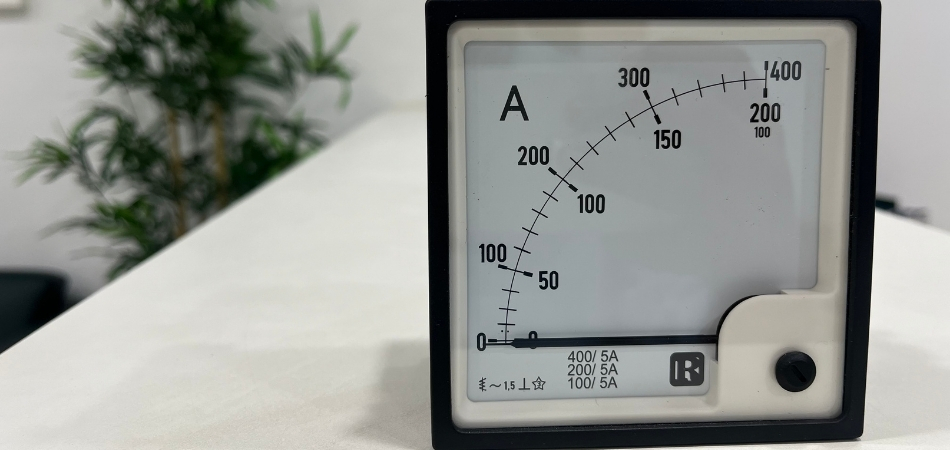

This factory wanted to make special housings for their instruments using injection molding. But they had a hard time. Mixing stuff was hard, and the final products weren't right. Plus, the housings lost their anti-static powers over time, causing big headaches. It felt like they were trapped in a maze with no way out.

Customer Background:

This big company wanted to make anti-static housings out of ABS using injection molding for their important production line. But they ran into lots of problems.

Challenges:

No matter how many times they tried with different mixes, they faced three big problems. Mixing was hard, making the molds was all over the place, and getting a smooth surface finish was like chasing a rainbow. The static resistance values were all over the place, refusing to stay steady.

Solution:

To fix their problem, they asked Flamingo India for help. Flamingo India suggested using GYC-At-300 Antistatic Additive, which could be added directly into the injection molding process.

Implementation:

The company carefully mixed just 1.5% of the additive with their ABS material. The additive came in granular form, so they didn't need extra gear, making things simple. They smoothly added the right amount into their injection molding machines, blending innovation with efficiency.

Results:

As the machines worked, something amazing happened. The housings came out with a lasting anti-static quality, even better than expected. Not only did they use a tiny bit of the additive, but the surface looked better than ever. With a static resistance value of 10^10, stability became the new normal.

Conclusion:

In the story of finding new ways, GYC's antistatic additive was the hero. It was easy to mix into the molding process, saving money and trouble. The company succeeded, feeling more confident in their production line.

Call to Action:

For all makers wanting to solve static problems, Flamingo India invites you to join them. Let's journey together as GYC's antistatic additive changes what's possible with injection molding. Let's unlock your creations' potential, together.